Preparing for U.S. Manufacturing Careers

Nov 11, 2025 12:30 PM

The American manufacturing renaissance is here, and it's bringing opportunities that haven't existed in decades.

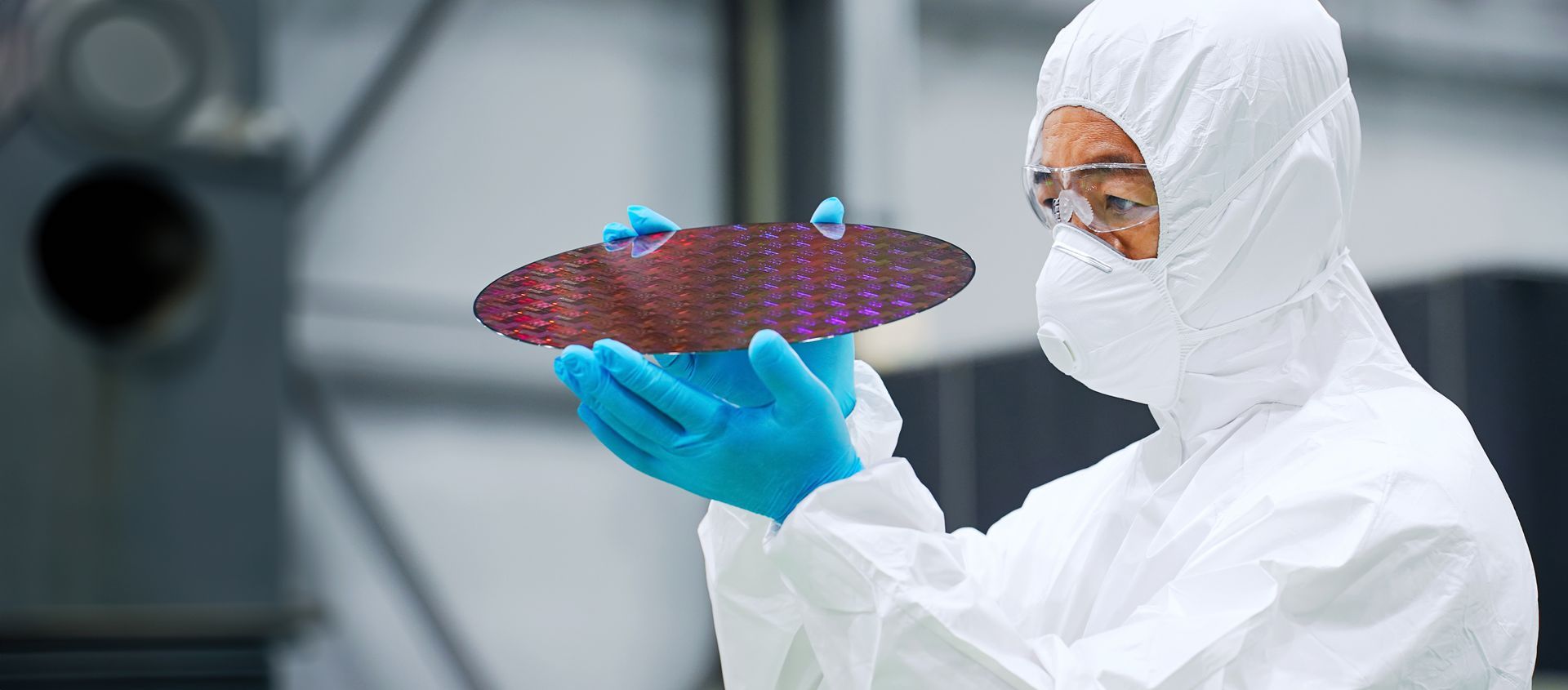

Walk through any industrial corridor in Arizona, Texas, or Ohio these days, and you'll see something remarkable: cranes dotting the skyline, construction crews working around the clock, and "Now Hiring" signs that actually mean it. After years of watching factories close and jobs move overseas, the tide has turned. Semiconductor plants, electric vehicle facilities, and battery manufacturing sites are rising across the country, and they need workers, lots of them.

But here's the thing nobody tells you: these aren't your grandfather's factory jobs. The manufacturing floor of 2025 and beyond looks more like a high tech laboratory than the assembly lines of old. That means the path to landing these roles requires some strategic thinking and, frankly, some hustle.

The Reality on the Ground

The numbers tell the story. Arizona alone has over 670 semiconductor job openings right now. TSMC's Phoenix facility is ramping up. Intel is expanding in Ohio. Samsung is building in Texas. These companies need production operators, process technicians, quality inspectors, maintenance specialists, and equipment handlers. Most of these roles start between $65,000 and $95,000+, with clear paths to higher positions.

Understanding What Employers Actually Want

Let's cut through the corporate jargon and talk about what really matters when you walk into an interview at one of these facilities.

Safety comes first not in a theoretical way, but in a "we're dealing with multi billion dollar equipment and hazardous materials" way. When TSMC interviews candidates, they're not just checking boxes on safety training. They're looking for people who genuinely understand that one mistake in a cleanroom can contaminate an entire production run worth millions of dollars.

This is why 92 percent of facilities make safety knowledge non-negotiable, and why 40 percent of applicants fail interviews on this alone. It's not enough to nod along when someone mentions OSHA regulations. You need to demonstrate that you grasp the consequences.

The second thing hiring managers look for is adaptability. Modern manufacturing equipment doesn't just require mechanical skills anymore. A maintenance technician at an EV battery plant needs to understand electrochemistry, thermal management systems, and how to troubleshoot automated assembly lines controlled by programmable logic controllers. That's three different skill sets converging in one role.

5 Things You Can Do To Prepare For A Career In Manufacturing

1. Get Safety Certifications First

Start with OSHA 10 Hour General Industry certification and cleanroom protocol training through SEMI.org. These are non-negotiable basics that 92% of facilities require. Add quick wins like forklift certification or EPA 608 for HVAC. Safety credentials show you're serious and understand the high stakes environment.

2. Enroll in Community College Programs or Bootcamps

Look for 1-2 year certificate programs in semiconductor technology, industrial maintenance, or electro-mechanical systems at local community colleges. For faster entry, seek out intensive bootcamps like Intel's 10 day Semiconductor Technician "Quick Start" or similar CHIPS Act funded programs. Many are free or low cost and teach the exact skills employers need.

3. Learn the Industry Language

Study the terminology that hiring managers want to hear: OEE (Overall Equipment Effectiveness), statistical process control, cleanroom protocols, and particle excursions. Use free resources like SEMI's Workforce Training Portal and read key chapters from "Semiconductor Manufacturing Technology" (free PDF via IEEE). Speaking this language in interviews immediately sets you apart.

4. Network in the Hidden Job Market

Since 70% of manufacturing roles are filled before public posting, join SEMI Foundation's "Workforce Connections" virtual mixers with recruiters. Attend open house events at new facilities. Use LinkedIn strategically by finding hiring managers and commenting thoughtfully on their posts rather than just applying to job boards.

5. Pursue an Apprenticeship

Apply for registered apprenticeship programs at companies like TSMC, Intel, or local manufacturers. These combine paid work with technical training (typically 1-2 years) and have 90% job placement rates. They're the fastest path from entry level to career establishment, often leading directly to permanent positions with benefits and clear advancement opportunities.

Bonus tip: While pursuing these steps, develop soft skills like attention to detail, teamwork, and systematic problem solving, employers value these as much as technical knowledge.

The Training Path That Actually Works

Here's where most career advice gets it wrong. People either assume you need a four year engineering degree (you don't) or that showing up with a good attitude is enough (it isn't). The reality sits somewhere in between, and the pathway is more accessible than you might think.

Start with safety credentials. The OSHA 10 Hour General Industry certification costs nothing if you access it through official channels, and it takes about two days to complete. Add cleanroom protocol training through SEMI.org's free modules, and you've covered the baseline that gets you in the door.

But don't stop there. The candidates who get hired fastest combine these safety basics with technical certifications that show they're serious about the field. A forklift operator license runs about $150 and takes two days at most community colleges. Basic soldering certification through IPC-A-610. EPA 608 certification for HVAC critical for cleanroom environments is available online for under $100.

These aren't impressive credentials on their own, but together they signal something important: you understand the industry and you're willing to invest in yourself.

Community colleges have become the unsung heroes of this manufacturing boom. Hudson Valley Community College in New York offers semiconductor technology certificates covering digital electronics and nanotechnology. Western Michigan University has programs specifically designed for EV technician roles. These programs typically run one to two years and cost a fraction of a traditional four year degree.

Then there are the bootcamps. Intel's Arizona campus, partnering with Maricopa Colleges, runs a 10 day Semiconductor Technician "Quick Start" program. It's intense, but it teaches you the terminology, the protocols, and the mindset you need. Similar programs have sprouted up in a dozen states, many funded by the CHIPS Act and offering free training to qualified applicants.

The Language of Modern Manufacturing

Here's something nobody mentions in the glossy recruitment brochures: you need to learn a new language.

This isn't about sounding fancy. It's about demonstrating that you understand how these facilities actually operate. OEE (Overall Equipment Effectiveness) is the metric that keeps plant managers awake at night. Particle excursions are the enemy in semiconductor manufacturing. Statistical process control is how you maintain quality at scale.

Learning this language doesn't require years of study. SEMI's Workforce Training Portal offers free resources. The book "Semiconductor Manufacturing Technology" is available as a free PDF through IEEE read chapters four and seven before any interview. Spend a few evenings with these materials, and you'll speak the language that matters.

The Hidden Job Market

Here's a frustrating truth: the best manufacturing jobs never make it to Indeed or Monster. By the time a position appears in a public job posting, dozens of people already know about it through internal networks.

TSMC filled 70 percent of its Arizona positions before posting them publicly. Intel's Ohio facility did something similar. This isn't nepotism—it's the reality of hiring at scale. Recruiters need to fill hundreds of positions quickly, and they naturally turn to their networks first.

So how do you break into these networks? Start by showing up where the conversations are happening.

SEMI Foundation runs free virtual mixers called "Workforce Connections" where recruiters from Intel, TSMC, and other major players actually participate. These aren't stuffy networking events, they're informal conversations where you can ask real questions and make genuine connections.

Many new facilities host open houses. Samsung's Taylor, Texas location does monthly tours. Show up with three copies of your resume and a few intelligent questions about the facility's timeline or training programs. Even if they're not hiring for your target role that day, you've put yourself on someone's radar.

LinkedIn has become surprisingly useful if you use it strategically. Instead of blindly applying to job postings, search for hiring managers at specific facilities. Find their recent posts and leave thoughtful comments. Not salesy pitches, actual insights or questions that demonstrate you're paying attention to the industry.

The Apprenticeship Advantage

If you're serious about manufacturing as a career, not just a job, apprenticeships offer the most direct path forward.

TSMC's Arizona apprenticeship program runs one to two years, combines on the job training with technical instruction, and pays you while you learn. About 90 percent of advanced manufacturing apprentices stay with their employer after completing the program. That's not just job placement, that's career establishment.

These programs aren't easy to get into, which is exactly why they're valuable. Companies invest serious resources in apprentices, so they're selective. But if you've already completed basic certifications, demonstrated interest in the field, and can articulate why manufacturing appeals to you, you're a competitive candidate.

The Soft Skills Nobody Talks About

Technical skills get you hired. Soft skills get you promoted.

Manufacturing environments demand teamwork in ways office jobs don't. When you're running a production line, you can't just fire off an email and move on. You need real time communication with operators upstream and downstream. You need to explain technical problems to supervisors who might not share your background. You need to train new hires clearly and patiently.

Attention to detail matters more than anywhere else. In semiconductor manufacturing, a particle smaller than a human hair can ruin a chip. In battery assembly, a misaligned cell can create safety hazards. You need the kind of focus that doesn't waver during hour eight of a twelve hour shift.

Problem solving ability separates technicians from great technicians. Equipment breaks. Processes drift. Materials arrive with unexpected variations. Can you troubleshoot methodically? Do you know when to escalate versus when to solve it yourself?

These aren't skills you learn from a textbook. They come from experience, from working in teams, from paying attention to how successful people around you operate.

Looking Ahead

The manufacturing boom isn't temporary. The CHIPS Act allocated $52 billion for semiconductor manufacturing. The Inflation Reduction Act is driving massive investments in EV and battery production. These facilities take years to build and decades to operate. The jobs they're creating now will be here for the long haul.

But timing matters. Companies are hiring and training now, ahead of full production ramps. If you wait until these facilities are fully operational, you'll be competing with people who already have experience working in them.

The pathway into manufacturing careers isn't mysterious. Get safety training. Acquire relevant certifications. Learn the industry language. Network strategically. Apply for apprenticeships. Show up ready to work hard and keep learning.

These opportunities exist. They're real, they pay well, and they're more accessible than most people realize. The question isn't whether there's room for you in American manufacturing's future. The question is whether you're ready to claim your place in it.